- HOME

- About Us

30 Years Eexperience in Extruding Aluminum Profile

WHO WE ARE?

In 1994, Jia Hua Aluminum was established in Foshan, China. With the rapid growth development, our company becomed one of the leading aluminum extrusion factories in China.We commit to satify with our customers by contributing of high quality and good service .Our development by pursuing the contribution of high quality and high service. We respect, trust, and cooperate with customers to achieve higher value for each other.

Product Range

Aluminum industrial profiles, Aluminum decorative profiles, Aluminum architectural profiles, Five major finished products :

Aluminum Wardrobe Profile

Aluminum Window & Door Profile

CNC Aluminum Profile

Cabinet Series

Sliding & Swing Door Series

Office Partition Series

Sliding Wardrobe Series

Full Glass Wadrobe Series

Kitchen Series

Aluminum LED Linear Light

Aluminum photos frame

Aluminum Mirror frame

Aluminum grills

Ceramic Series

Online Factory Tour

Our company’s registered capital is RMB 30 Million. We employ over 1000+ staff. Our professional factory covers an area of 75000+ square meters. We have cultivated a team of engineers with over 30 years experience, introduced advanced manufacturing equipment from home and abroad, built 23 extrusion production lines, and accumulated over 50,000 molds. Every year, we output 60,000 tons of aluminium profile.

Competitive Advantages

Established in 1994, Jiawah Aluminium Company Limited has accumulated more than three decades of expertise in aluminum extrusion manufacturing. Located in Foshan, China’s aluminum industry hub, the company operates a 75,000+ square meter modern production facility with 23 advanced extrusion production lines. With an annual production capacity exceeding 60,000 tons, Jiawah Aluminium is well-equipped to handle high-volume, long-term projects while maintaining consistent quality and on-time delivery. This scale and experience provide customers with a reliable, stable supply chain and strong production flexibility.

Jiawah Aluminium has built a strong technical foundation supported by an experienced engineering team with over 30 years of industry know-how. The company has accumulated more than 50,000 molds, enabling rapid product development and efficient customization for diverse applications. We offer full OEM and ODM services, covering product design, mold development, extrusion, CNC machining, surface treatment, and final packaging. Our wide product portfolio—including aluminum profiles for windows and doors, wardrobes, cabinets, office partitions, LED lighting, and decorative systems—allows us to provide one-stop aluminum solutions tailored to the specific requirements of international markets.

Quality and reliability are at the core of Jiawah Aluminium’s operations. The company is certified to ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), and ISO 18001 (Occupational Health & Safety Management System). From raw material inspection to extrusion, machining, surface finishing, and final inspection, every production stage is controlled under standardized procedures. By combining international management standards with advanced manufacturing equipment sourced globally, Jiawah Aluminium ensures products that meet or exceed global quality expectations, helping customers enhance product performance, brand reputation, and market competitiveness.

Our Partners

We position ourselves as a China-headquartered global aluminum profile solution provider, helping clients develop differentiated products to gain greater market share.

Principle Service

Our commitment to quality is unwavering, demonstrated through our robust 3 confirmations +1 guarantee system. We start with Sample confirmation to ensure the initial product meets your specifications. Prior to bulk production, we conduct a Confirmation before bulk production, meticulously checking every detail. Post-production, our Inspection and confirmation process rigorously verifies the quality of each batch. Complementing these confirmations, our contract commitment guarantee ensures that all products adhere strictly to the agreed-upon terms and quality standards. With Zhonglian Aluminum, you can trust that every product will exceed your expectations in both quality and reliability.

Manufacturing Equipment & Production Lines

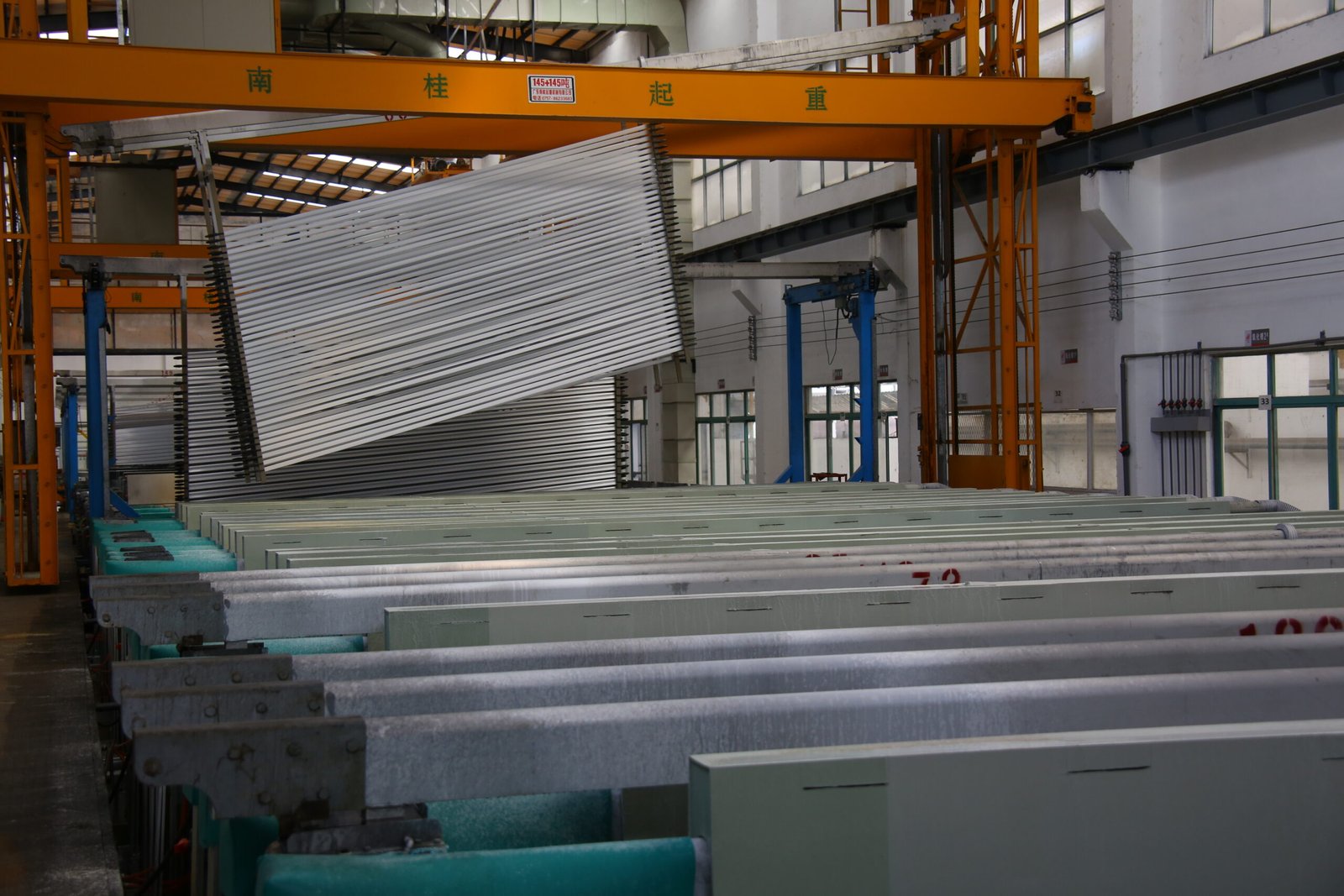

Jiawah Aluminium Company Limited is equipped with advanced manufacturing equipment and highly efficient production lines to ensure stable quality, high precision, and large-scale output. Our factory operates 23 aluminum extrusion production lines, covering a wide range of sizes and specifications to meet diverse application requirements. By introducing state-of-the-art machinery from both domestic and international suppliers, we are able to maintain excellent consistency, dimensional accuracy, and surface quality across all products.

From extrusion and CNC machining to surface treatment and finishing, each production stage is well-organized and strictly controlled. Combined with our experienced technical team and standardized management systems, our manufacturing capability allows us to deliver high-volume orders, customized profiles, and fast lead times while meeting international quality standards. This strong production foundation enables Jiawah Aluminium to serve global customers with reliability, flexibility, and long-term supply assurance.

Extrusion Workshop

Loading Area

Mold Workshop

Oxidation Workshop

Horizontal Spraying Workshop

Wood Grain Workshop

Powder Coated Workshop

Extruder Workshop

Oxidation Workshop

Powder Coating Workshop

Workshop

Aluminum Ingot

CNC Workshop

Automatic Oxidation Control Room

Anodized Workshop

Extrusion Machine

Professional Surface Treatment

Certificates

Our products and services have passed strict official and authoritative certifications, including ISO 9001, ISO 14001, CE, TUV, ROHS, SGS, KS,etc.

Strict Quality Inspection

Quality assurance is a core priority at Jiawah Aluminium Company Limited. We implement a strict and comprehensive quality inspection system throughout the entire production process, from raw material incoming inspection to extrusion, machining, surface treatment, and final packaging. Each stage is monitored under standardized operating procedures to ensure dimensional accuracy, mechanical performance, and surface quality.

Packing Reference

Jiawah Aluminium Company Limited provides safe, professional, and flexible packing solutions to ensure aluminum profiles are well protected during storage and international transportation. Standard packing options include protective film, shrink film, foam, kraft paper, carton boxes, wooden pallets, and wooden crates, which can be combined according to product type and shipping requirements.

Global Business Partners

Development History

Founded in 1994 in Foshan, China, Jiawah Aluminium Company Limited began its journey with a clear focus on aluminum extrusion manufacturing. Over the past 30 years, the company has continuously expanded its production scale, upgraded equipment, and strengthened technical capabilities in response to market demands and industry development.

Jia Hua Aluminum was established in Foshan

Obtained the quality management system certification and the national industrial product production license.

Jia Hua obtained the honorary certificate of "China Famous Brand".

Obtained the title of "Top Ten Key Enterprises" and "Guangdong Famous Trademark".

Obtained the title of " Guangdong Famous Brand Product". Create a sub-brand "Pailian".

Set up a branch factory for CNC processing aluminum profiles and create a sub-brand "Zhongchang Aluminum".

Entered the new modern office of the Ministry of International Trade. Annual Export US $20,000,000.

Live up to expectations, go forward! Need aluminum materials? Go with JiaWah, your reliable China aluminum supplier.

Team Introduction

At Jiawah Aluminium Company Limited, our success is driven by a highly skilled and dedicated team of over 1,000 professionals, including engineers, technicians, and support staff. With more than 30 years of collective industry experience, our team brings deep expertise in aluminum extrusion, CNC machining, surface treatment, and product design.

Get in Touch Now

Let’s Start A New Business Today